Different designs of thread rolling dies available in Metric and Inch sizes for Machine screw in the field of Machine Building, Automotive and Industrial fastener applications.

Boltmaker single face dies have a threaded profile that provides a uniform rate of penetration over approximately two-thirds of the die length. The remaining dwell section accurately sizes the thread. These dies can be used for rolling ASME 1A,2A and 3A as well as ISO class 6g and 4h right hand, single lead threads.

Kadimi standard Boltmaker dies are made from tool steel and suited for general purpose applications.

Dies can be supplied on a special basis for other machines and face depths, as well as from other special materials. In addition, other special thread forms, left hand threads and multiple leads can be supplied.

Duplex dies have threads on both faces, offering twice the life of single face dies. Four settings may be used with duplex dies when the depth of the face is in excess of two thread lengths. These dies can be used for rolling ASME 1A,2A and 3A as well as ISO class 6g and 4h right hand, single lead threads.

The minimum depth of the die face should be at least two pitches greater than the length of thread to be rolled. Select the nearest larger depth of the die face whenever possible.

Dies are treated with special proprietary surface treatment which provides even higher performance when rolling difficult to form materials.

Dies can be supplied on a special basis for other machines and face depths, as well as from other special materials. In addition ,other thread forms, left hand threads and multiple leads can be supplied; either as Duplex, single or split face dies.

At Kadimi we adapt to the customer's needs, manufacturing single face, split-face style, or duplex thread rolling dies to obtain higher performance from the tool.

Kadimi LF dies are developed to help roll the best quality fasteners without modifying any of the processes (e.g. blank preparation and machine operation). In controlling manufacturing variables to yield lap-free thread fasteners, LF technology

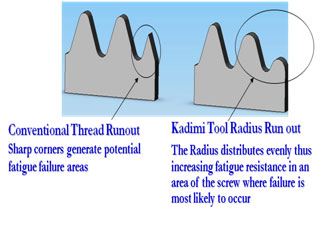

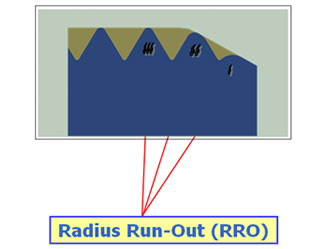

Flat thread rolling dies with sharp corners on the run out threads generates stress concentration areas which result in fatigue cracks in the thread rolled screw. With the Radius Run Out (RRO) offered by KADIMI, the smooth radius in the root of the thread continues right up to the point where the thread blends in the shank of the screw. This Radius Run Out was designed for rolling high strength aerospace bolts, however, it is available on all KADIMI dies.

Dies to be used for machine screw having straight flutes at point with incomplete threads allowing for heavy paint drizzled into the tapped holes be removed. Unthreaded Screw blanks are tapered at the point.Dies produce straight flutes during thread rolling.Meets the locking standards thereby extreme resistance to vibrational loosening brings them categorically as self-locking asteners under conditions of severe vibration or high clamp load.

Combination type of machine screw die with two or more thread profiles, available in different sizes and thread forms; mostly used in Studs .Studs provide the ability to obtain much more accurate torque values because the studs don’t twist during tightening as do bolts and tends to remain stationary during nut tightening, the studs stretch in one axis alone, providing much more even and accurate clamping forces. Also, the use of studs results in less wear applied to the block’s threads, this extends the life of the threaded holes in the block over periods of servicing/rebuilding.

Machine screw dies having bolt maker taper, having threads on one side of the die only. It can be single or two way setting. Recommended for Lap free rolling and After Heat Treatment Rolling(AHT).Boltmaker style thread rolling dies can be used in other thread rollers i.e. Waterbury Farrel, with the use of suitable backing blocks.

These are special Flat ground thread rolling dies for machine screw for providing chamfer; these are straight faced die(Single or Duplex) with Insert for different angles for chamfer as per customer requirement. Dies are designed to add a chamfer to the end of a straight blank and to roll threads into the chamfer.