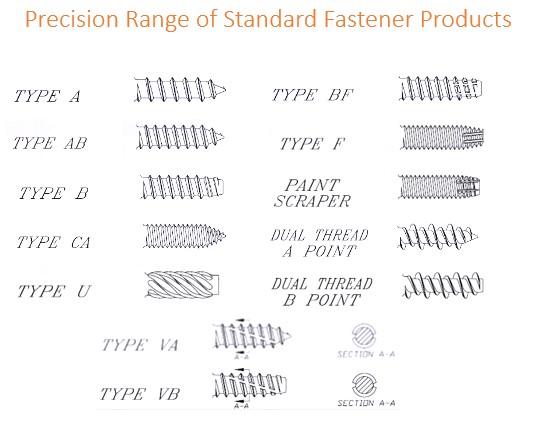

There is wide range of flat thread rolling dies for different applications of tapping screws.

|

Standardize lead thread shape,ensuring everymanufacturer produces the samethread reducing the

set-up time and complexity. Improves the fastener’s ‘False-thread’ prevention.

It makes even shorter MATpoint® products possible.

(Image & Info. Courtesy: MAthread).

Kadimi manufactures flat thread rolling dies considering the specific needs of our customers very much into account. Kadimi offers customization in accordance to the required material and machinery specifications Our designs facilitate minimizing machine set up times and providing significant savings on costs per each threaded piece

Kadimi LF dies are developed to help roll the best quality fasteners without modifying any of the processes (e.g. blank preparation and machine operation). In controlling manufacturing variables to yield lap-free threadd fasteners, LF technology

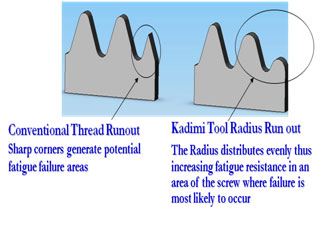

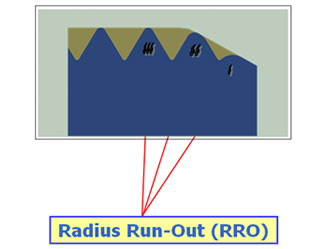

Flat thread rolling dies with sharp corners on the run out threads generates stress concentration areas which result in fatigue cracks in the thread rolled screw. With the Radius Run Out (RRO) offered by KADIMI, the smooth radius in the root of the thread continues right up to the point where the thread blends in the shank of the screw. This Radius Run Out was designed for rolling high strength aerospace bolts, however, it is available on all KADIMI dies.